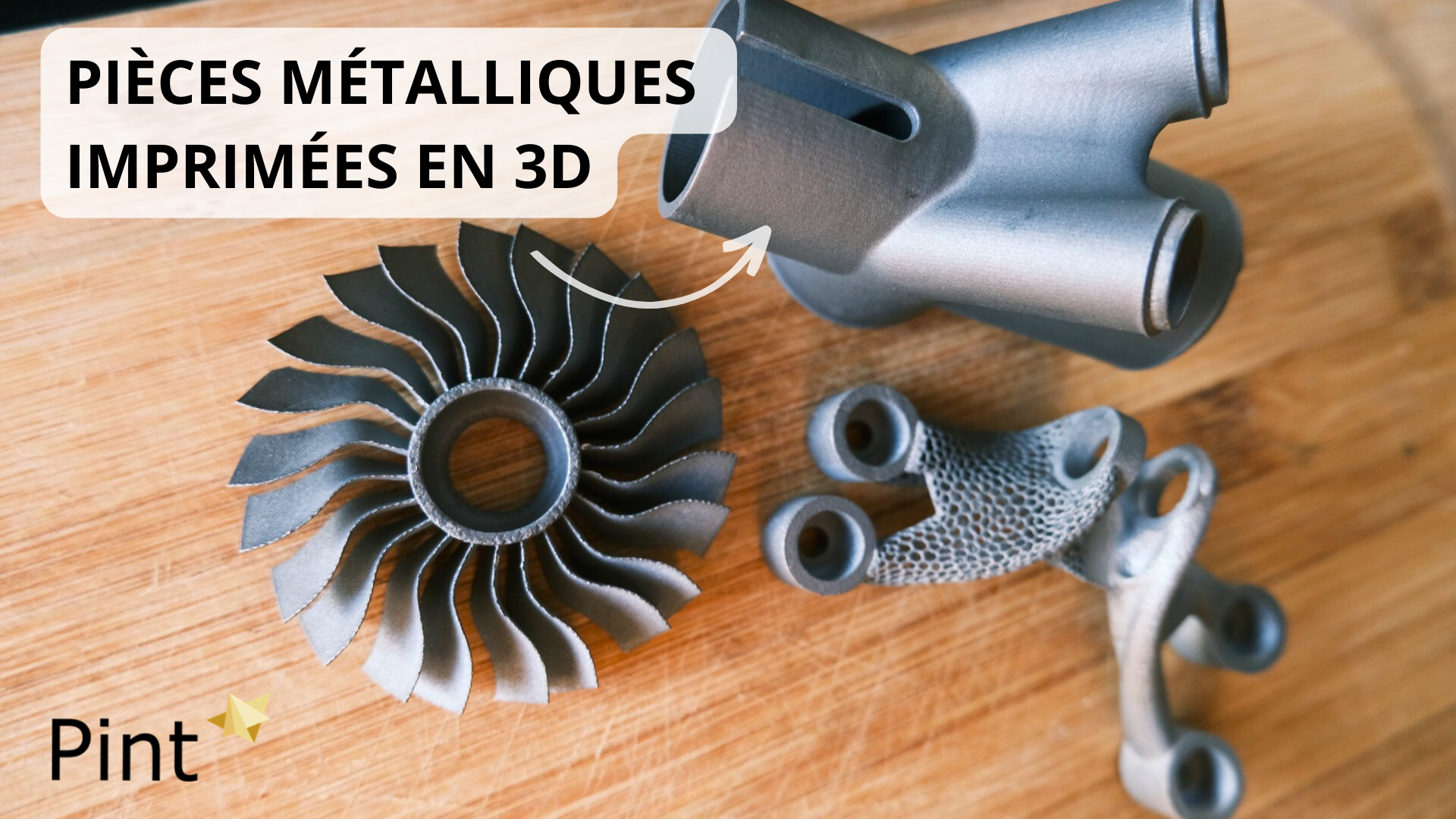

Pièces métalliques variées, en différents alliages (titane, d’acier, d’aluminium et cuivre)

Comment votre société s’est-elle constituée ?

Pint est issue, en 2021, de travaux de recherches au sein du laboratoire LEM3 à Metz (Laboratoire d’Etude des Microstructures et de Mécanique des Matériaux), qu’elle s’est donnée pour but de valoriser. On peut ainsi nous qualifier de start’up industrielle. Nous sommes aujourd’hui une équipe de quatre personnes et allons dégager un premier chiffre d’affaires à l’issue de cet exercice 2023. Nous sommes hébergés pour l’heure par le laboratoire, avec l’intention de croître, de sorte à s’installer dans les deux ans dans des locaux dédiés, avec notre propre matériel.

Quelles spécialités développez-vous ?

Nous sommes actifs dans l’impression 3D métallique. Celle-ci permet de réaliser des pièces mécaniques aux formes les plus variées possibles : l’impression 3D repousse les limites de la géométrie ! De plus, le savoir-faire que nous avons développé à partir des recherches initiales nous permet de mettre au point des alliages spécifiques, à base notamment de titane, d’acier, d’aluminium et cuivre. Nous pouvons ainsi confectionner des pièces présentant des caractéristiques particulières de résistance, de rigidité ou encore de déformation sous l’effet de la chaleur, par exemple.

Nous utilisons un procédé de fusion laser sur lit de poudre qui commence à se développer, nous participons ainsi à son déploiement et à une certaine démocratisation. Nos solutions s’adressent sur le principe à tous types d’industrie, il n’y a pas d’exclusive de ce point de vue. Dans les faits, pour l’instant, nous nous sommes implantés commercialement dans les secteurs des transports, du médical et du spatial plus particulièrement.

Vous exposez pour la première fois à Be 5.0 – Industries du futur, quel a été votre cheminement pour prendre cette décision ?

Nous avons découvert Be 4.0 – Industries du futur à l’occasion de son édition 2022, en tant que visiteurs. Nous avons été séduits par son format, régional, ni trop grand pour se « diluer » dans les allées et les stands, ni trop petit pour rester anecdotique. Nous avons noté aussi avec intérêt la présence à la fois de sociétés industrielles et d’autres proches de l’univers de l’innovation, la réunion de ces profils sur un seul site nous a semblé pertinente. Ce rendez-vous 2023 de Be 5.0 s’annonce ainsi comme prometteur pour capter l’attention de l’industrie régionale, qui fait partie de nos cibles prioritaires, au sein d’une clientèle que nous commençons à attirer dans toute la France et dans le reste de l’Europe.

Quelles sont les informations que vous allez communiquer à l’occasion du salon ?

De façon générale, nous allons rappeler les avantages de l’impression 3D métallique : économie de matière, allègement du poids des structures, simplification des assemblages, et donc diversité des formes de pièces. Nous présenterons un cas d’application dans le ferroviaire. Nous parlerons de nos projets de développement, qui pourraient aussi passer par une levée de fonds à plus ou moins long terme.

Propos recueillis par Mathieu Noyer, rédacteur en chef de Traces Ecrites News, le site d’information économique du Grand Est et de la Bourgogne-Franche-Comté (www.tracesecritesnews.fr)

.png)